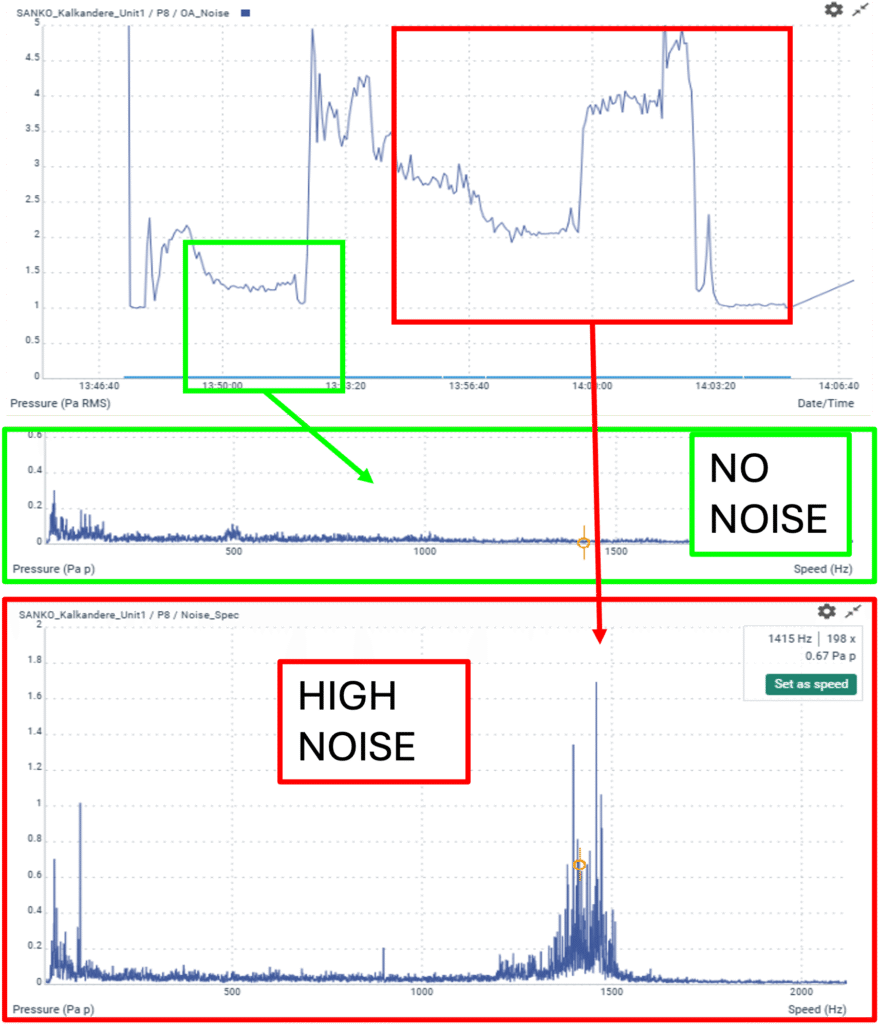

An unusually high-frequency noise problem has been observed in one of the turbines operating at a hydroelectric power plant, occurring within specific load ranges. The noise becomes particularly noticeable when the load is between 45–55 per cent and is perceived as disturbing by operating personnel.

To identify the source of the problem and resolve it permanently, the Resonance Institute’s team of experts conducted a vibration and acoustic analysis study.

Measurement and Analysis Method

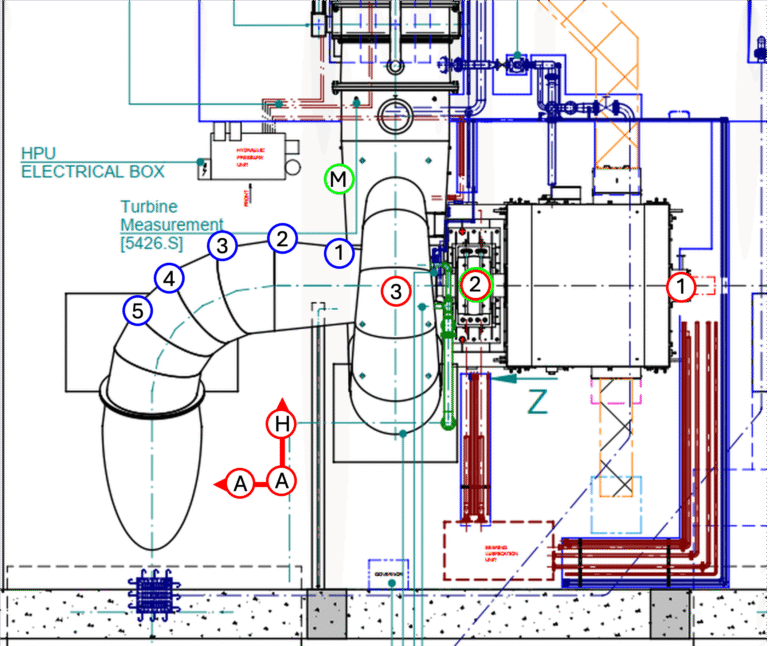

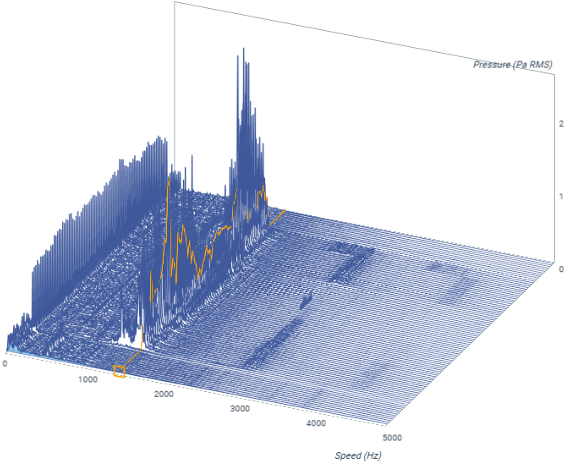

In the study, multi-point measurements were taken using vibration sensors and microphones placed on the turbine-generator body and draft tube area. The data were evaluated using Twave analysis software and analysed based on the ISO 20816-5 standard.

Although the overall vibration levels were within the limits of ‘A: New Machine Condition’, a notable anomaly was detected in the acoustic spectrum under certain operating conditions.

Findings

Analysis results;

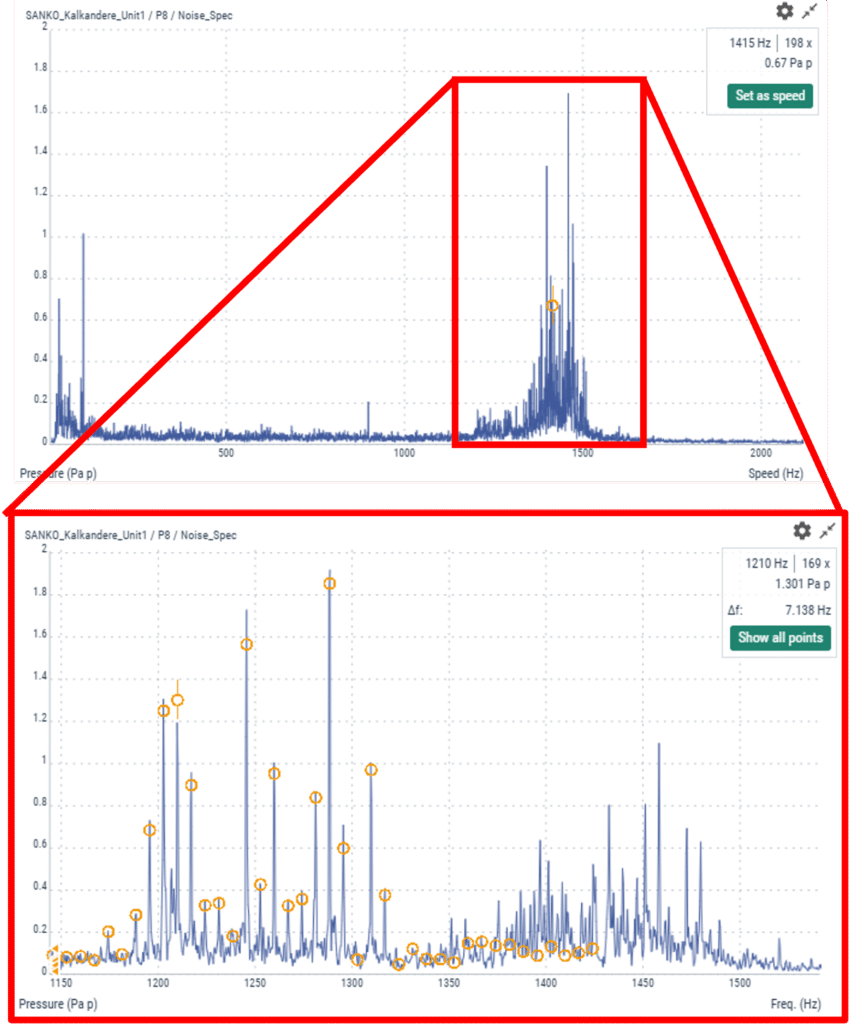

The noise has a broadband structure in the 1200–1500 Hz range,

The noise components show modulation at 7.1 Hz (1X – impeller rotation frequency),

The noise only suddenly increases during the loading manoeuvre,

The source is the impeller – guide vane – draft tube interaction region.

These findings are fully consistent with the vortex shedding phenomenon described in the literature. In particular, it has been assessed that small geometric deviations at the blade tips create local vortices in the flow, which in turn cause high-frequency acoustic resonance.

Corrective Action and Results

As a result of the analysis, it was recommended that the impeller mounting tolerances and guide vane alignment be checked, and that local grinding be performed on the vane tips to prevent vortex formation.

Following these improvements, the turbine was recommissioned and the noise problem was observed to have been completely eliminated. Acoustic measurements confirmed that the high-frequency components identified in previous tests were no longer present.

Conclusion and Evaluation

This study demonstrates how effective the combined application of vibration and acoustic analyses is in identifying and resolving complex flow-induced problems in hydro turbines.

Through this analysis, the Resonance Institute:

Accurately identified the physical cause of the noise problem,

Recommended a targeted correction, avoiding unnecessary mechanical interventions,

Enhanced operational comfort and system efficiency with a simple yet effective geometry improvement.

This success once again highlights the critical role that data-driven engineering approaches play in achieving reliability, quiet operation, and long service life in energy production systems.

English (İngilizce)

English (İngilizce) Türkçe (Turkish)

Türkçe (Turkish)